When something doesn't work anymore it's value drops to zero. Keep your eyes open because you can find useful stuff that has fallen into disrepair, buy them for almost nothing, or free, and then repair them, and you'll have a good working tool. I have a need to cut up fallen tree limbs into firewood. Cutting large tree branches with a hand saw is tedious, and time consuming. This motivated me to find a Chainsaw for cheap, or free, then do whatever I needed to do to get it working.

I had actually worked on this Chainsaw once before. I did a minor tune up where I replaced the fuel filter, the air filter, and the spark plug. It worked for a while after that, and then became very difficult to start, and ultimately wouldn't start. I assumed that the seals within the carburetor had failed, and the fuel mix was out of tolerance. The person that owned this chainsaw became convinced that it was just broken, and nothing could be done to repair it, so he wound up giving it to me.

Then it sat on my patio for about four years. I had interest in repairing it, but had never found the time. Well, now I have a stack of tree limbs that I need to break down into pieces that will fit into my smoker. The limbs are Pecan, and Live Oak, and I like Barbeque that is smoked with Pecan, and Live Oak woods. So, ultimately, the motivation to repair this chainsaw is my appetite for barbeque.

There maybe about a decade of crud built up on the outside of this chain saw. So, I start with the de-crudification process. This involves brushing, scraping, spraying, and scrubbing to get all the crud out of the way of the working parts. I am using Carburetor Cleaner, and Gasoline as solvents to loosen up the crud. Then I used brushes, paper towels, and compressed air to liberate the crud.

Before I started this process I did a search on U-Tube to find a tutorial on rebuilding Shihl Chainsaws. That was very helpful in that it showed me everything I needed to do.

Here is a link to the tutorial. There are two fuel filters that should be replaced. One is a cylindrical filter in the fuel tank, and the other is a fine screen that is within the carburetor. I couldn't find a carburetor kit to rebuild the carburetor, but did find a replacement carburetor. We are going to replace the entire fuel system, except the fuel tank.

This chainsaw had a fuel system problem, most likely within the carburetor, and the correct action is to replace all of the suspect parts. We have a new carburetor, a fuel line, a tank fuel filter, an air filter, and a new spark plug. Altogether, maybe about $40 of parts. You can do this cheaper by getting a carburetor kit if you can find one.

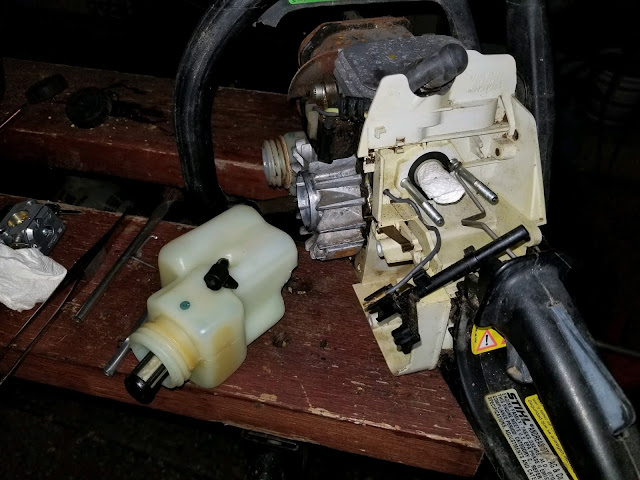

Now I have the whole area cleaned up, and am starting to re-assemble the chainsaw with the new parts. Here I have cleaned the fuel tank thoroughly, installed the new fuel line, and tank filter. I am impressed with Stihl's design for this chainsaw. It is nicely simple, with the lowest number of fasteners possible. The plastic parts are UV, and solvent resistant, and all seem to be in really good condition for a 10 year old chainsaw. The one part that was broken was the Chain Brake Lever.

The linkages for the Choke, and Throttle are precisely bent heavy wire that doesn't need any fasteners. That is exceptional because all of this is really small already, and having fasteners in these areas would require that they be even smaller. Simple is better, and more rugged.

After the chainsaw was fully assembled I fueled it up with a premium, pre-mixed, 2 cycle fuel designed specifically for Stihl small equipment. This premium fuel is significant because it does not contain Ethanol. The seals, and fuel lines in these small power systems do not like Ethanol. The Ethanol attacks the rubber seals, and fuel line, and causes them to breakdown over time. So, if you can, only use a premium fuel designed for your small power equipment, and DO NOT use Pump Gas.