Saturday, December 24, 2016

Let It Snow!

Sunday, December 11, 2016

RX300 Windows Tech Brief

You are specifically interested in the PC Board pattern, and schematic of the Relay. This gives you the information about how the relay is wired onto the Door Control Board. Now here is the ACJ2112 part specification.

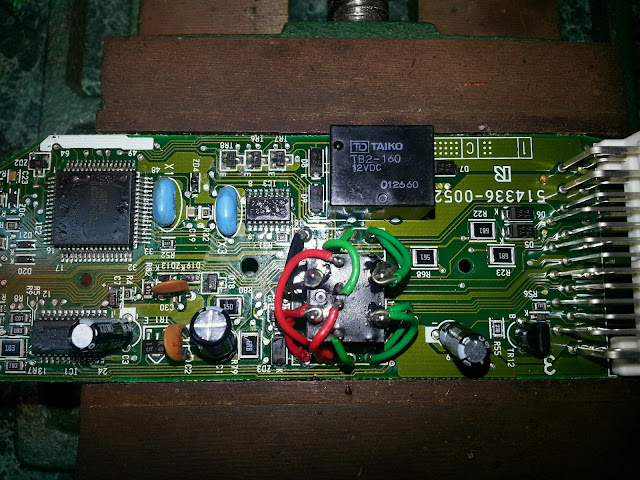

Note that the ACJ2112 is considerably smaller than the CR2-12V. Both parts are shown from a bottom view, but we will be using the Dead Bug Technique to wire in the replacement relay, so the connections will be mirrored vertically relative to the CR2-12V part specification drawings, example below. Here is a shot of the Dead Bugged Relay.

Alright, this is where it gets tricky. You are looking at the top side of the circuit board, so the CR2-12V footprint is mirrored vertically. Then we are going to put the ACJ2112 down, up side down, within the CR2-12V's footprint, with the common contacts oriented to the right, to the window motor. The Normally Open, and Normally Closed contacts go to the power supply side. Then the coil contacts are in the middle.

I cropped the schematic diagrams out of the part specifications, and reoriented them to the positions they have in the photo above. Notice the way the common contacts are touching the Normally Closed side of the relay, and how they are both on the top. Here we have aligned the relay switching position. This is how you verify that the up switch will make the window go up, and not down. There are three opportunities here to wire this backwards. The common connections go to the window motor, wire them backwards, and the window works in reverse. Like wise if you wire Normally Open, and Normally closed backwards the window also works in reverse. If you get the control signals to the coils wired backwards the window works backwards. So you really need to pay attention to which wire goes where.

As for wiring, the heavy current wires are Commons, to window motor, and Normally Open, and Normally Closed, which go to the power supply. These wires can carry 20 Amps, so they need to be at least 18AWG, 16AWG would be better if it will fit. I plan on using 18AWG Solid wire to connect the heavy current terminals. Soldering large wire like this will require a soldering iron with enough power to heat the larger mass of the wire, and circuit board. If you are having trouble getting the solder to flow, find a more powerful iron. The solder joints carry current, and need to be flowed correctly. The coil wire, as you can see in the specification above, only carry about 50 milliAmps, so the control wires to the coils can be 24AWG Solid wire. I used a 5 minute epoxy to glue to ACJ2112 to the circuit board.

This Tech Brief takes time, and effort to produce. There is a Donation button at the top of this page, please contribute to my effort to keep Kick Ass Toyotas (RX's specifically) working like they should...

Ultimately I wound up replacing these with aftermarket boards. There are a lot of cheap Knock Offs now. The first sucked, literally, and would drain the battery.The second worked better, but has a glitchy thing with the locks when I close the driver door. Cheap Knock Off are just that. It would be nice to get some genuine Toyota parts, LOL!

Wednesday, December 7, 2016

RX300 Windows

The replacement is a newer Panasonic ACJ2112, Dual 1 Form C Relay, designed specifically to be a power window relay. The good news is that this part is smaller, and easily fits within the footprint of the old part. The bad news is the pin out is not the same, and we'll have to wire the part in, not a big deal. I searched a long time for this part, and it appears to be the right part for the retrofit. The large current terminals on the new relay are oriented the same as the original relay when they are upside down. This means the designers were savvy to the eventual retrofit. Here is a shot of the original relay.

I'm using two 22AWG Solid Core wires for the connections that carry the window motor current. The Coil wires are 24AWG Solid Core wires. I'm gluing the relay down, using solid wire, and making the solder joints as robust as possible in order to withstand vibration. This is an automotive application, lots of vibration occurs, gotta make it hard.

The passenger side window is the worst one in the case of the intermittent operation. So it is the first one that I attempted this repair on. It worked right the first time, LOL! I carefully thought through the replacement using the datasheets for both the relays, got the wires worked out before I started the operation, and double checked my ideas again during the operation. Now I have three more to repair, presently. I bought extra parts to fix more if I need to. Anyone having RX300 widow trouble?

Saturday, November 26, 2016

Truk Restoration

One thing that I have trouble with for a long time is the Air Mix Servo on the Environmental System. It makes a buzzing sound when trying to switch vent outlets, and never quite gets to the end position. It is a worm drive servo, and the specific part that wears out is the bumper that the worm gear works against. You'd figure they would put a hard surface there, but its just plastic. When the worm gear moves out of its position it looses contact with a drive pin that is on the motors shaft. Then it is skipping in, and out of the worm drive, making that annoying buzzing sound. The fix for this one was to push the worm gear bumper closer to the worm gear to hold it in place. I took a tiny piece of 0.032" aluminum, and made a small spring to hold the worm gear bumper in place. That one works great. At the bottom left of the enclosure, on the left side of the worm gear you can see a gap between the worm gear, and the worm gear bumper. That is the problem. I filled the gap between the bumper, and the enclosure wall to push the worm gear bumper towards the worm gear.

RX300 Windows are unique in their misbehavior. There are times when the window goes down, but will not go up until the window is all the way down. Other times the window goes down, and does not go back up. Then there is another mode where you use the Auto Rollup feature, the window goes all the way up, hits the top, and then rolls down halfway, then only goes down. LOL! that one is the Best! Especially in a Thunderstorm...

This RX300 window system is microprocessor controlled, and networked. The master control talks to the other doors, and problems with the master controller will effect the other door controllers. Sometimes the master door control won't operate windows on the other doors, and you have to use the specific door control. There are a lot of interconnections, and all the buttons are soft switches, and not metallic conductors, thus a little more susceptible to contamination due to low current. The window controllers can get water in them which also causes problems.

The problem with the Auto Rollup was the Window Regulator Motor installation. When you install a new Window Regulator Motor you need to initialize it so that the Auto Rollup feature works correctly. If you skip this step the window motor will never work correctly. To do this you need to electrically hookup the motor, and controller before you install them into the door. They need to be separate from the window regulator. Use the Auto Rolldown switch to run the motor down until it stops. Then use the manual up switch to run the motor up 10 revolutions. Install the motor in the regulator at the middle of the window travel. Install the window regulator into the door. Then you will have to use the manual down switch to move the regulator to the point where you can install the window glass. Once you get the glass back in the door you need to use the manual down switch to roll the window all the way down. Then use the manual up switch to roll the window all the way up, and hold it for 5 seconds after the window closes. Then you can test the Auto Rollup feature before putting the rest of the door back together.

Probably the most annoying behavior of these windows is the intermittent behavior. They can sometimes work perfectly if the phase of the moon, and humidity are correct. They misbehave the most in inclement weather. I've had them refuse to rollup in rain, and freezing weather, and it motivated me to fix it. Turns out this is a worn out relay problem. The contacts on the relays are oxidized, and make intermittent contact. Sometimes works, sometimes don't... The solution here is to replace the relays. The trouble is they are obsolete, hard to find, and expensive when you do.

A couple days later I picked some parts from Ali Express, search for CR2-12V. I should get them in a week or so. Then we can fix that annoying window problem.

Update, Ali Express refused my order because they no longer have stock. The search continues...

I had some rattling noises coming from the front end. I assumed that this was the extremely worn struts, which made plenty of noise on their own. After replacing the struts, this rattling noise persisted. After some exploration I found that this noise was the links on the ends of the sway bar, called a stabilizer bar by Toyota. The ball ends were worn out, and bumping around. That is an off-the-shelf part at the Monster Truk store. So that was a fairly easy fix, four bolts, and the rattling noise was gone.

Probably one of the hardest problems I encountered, one that directly affected the State Inspection was a Check Engine light because of a small leak in the Evaporative Control System. This one has been big trouble, and has taken a lot of time. It is a vapor collection system that stores gas vapors in a charcoal can, then feeds these vapors to the intake manifold periodically. You can hear the engine surge slightly when the EVAP System opens the purge valve. Its basically a vacuum system that gets stretched all over the Truk. Fresh air supply lines go from the air cleaner to the EVAP Charcoal storage can, under the trunk stowage. Then a vapor line goes to the purge valve on the intake manifold. So this vacuum line has stretched across the Truk twice now. Then there is a line that goes to the Gasoline Fill Tube which is sealed by the Gas Cap, a part of the EVAP System. There are a couple other valves, and pressure sensors which monitor the EVAP System. The code my system gave is P0442, small leak in the EVAP System. I think I fix it, then a couple days later the light comes on again... Blarg...

Monster Truk is running a little better now, and got all his papers...

Thursday, June 23, 2016

The Do-Rag Incident

Sunday, May 8, 2016

Flux Suckerz Lite

Notice you can't see much light through the Carbon Filter. The two fans on the left have the filter installed, and the fan on the right doesn't. One of my tasks is to cut the rest of the filter material into replacements.

Crawler Tuning

Iz also wiring the brainz. Wiring is always kind of a mess, and I start with leftover pieces of other projects from my multitudinous scrap buckets. There was a time where I wired everything through a terminal block. Now I am more PCB-centric, but still use those old phenolic blocks every once in a while.

Once you get the wires under control it starts looking better. I have adapted these Brainz from another project so I will have to do some rework to make it compatible with what I am doing now. I've got a better potentiometer for the speed control, so the green pot on the board is going. Then I need to rewire the ICSP connector. I've been using a PICKit3 lately, and the ICSP connector needs to conform to the pinout on the PICKit3. Before I was using PWM as a signal to control a motor. This time I want to modulate power. So, I need to replace the bipolar 2n2222 transistor with a power MOSFET, probably a IRFZ44.

Then I need to add connectivity to the wireless module. We picked Bluetooth, so there is one interface. Then there is the sensor which is another serial peripheral type device. There is also another structural piece, a place to mount the sensor. I'm thinking about making a bent piece with thin (0.032") Aluminum, still musing tho...

Tuesday, May 3, 2016

Flux Suckerz (TM)...

I had some complaints about lack of power, which I had sacrificed for low noise. OK, this time I bent it the other direction, Mo Power. Three times more powerful. They still have the switched potentiometer, so you can dial them down. The totally minimized design on the right is the current one. The one with the black box was an earlier revision. Here is a look at the evolution of Flux Suckerz (TM)...

Thursday, April 28, 2016

Crawler Brainz

Tuesday, April 19, 2016

Crawler Drivetrain

Sunday, April 17, 2016

The Crawler

Also I found a battery holder that I can tuck under the frame rail that was modified. This gets the battery off the top of The Crawler so there is more space for the microcontroller board, and test equipment. Another thing that needed to be modified was the motor shaft. It has a notch in the 1/4" output shaft, and the Pulley is round in its bore. So a made a 0.060 inch thick piece from a 1/4" shaft to fill in the notch in the motor drive shaft. This holds the pulley more squarely on the motor drive shaft, and helps alleviate periodic strain on the drive system. The pulley is still kind of eccentric, and causes periodic strain on the drive system. Its something I need to fix next.

Monday, April 11, 2016

Crawler Test Platform

The really slow motion is provided by a Worm Gear Motor, which you could think of as a clock motor. It provides the spinning force which can be less than one revolution per minute. The Worm Gear Motor that is on the Crawler now is 64 RPM. I bought a couple more Worm Gear Motors also, 14 RPM, and 24 RPM. I'm still working on the drive mechanism, and the goal is 0.1 Miles per Hour. The overall speed has a lot of factors like the weight of the platform, and test equipment, friction through the drive train, the Voltage applied to the Worm Gear Motor, and even the friction of the tires on the surface. With all of these factors I want the end speed to be 0.1 MPH, or 8.8 feet per minute.

1.5 inch Aluminum angle bracket, and a 5" x 10" piece of 0.625" Aluminum make the frame on the Crawler. My starting point on this project was a robot platform with tank treads. The treads were the first idea to get thrown out because they were hard plastic, and would do nothing but slide on a hard surface. Then the frame of the robot platform was pretty irregular, hard to route the belts, so it got replaced with the Aluminum pieces. This way all the mechanization is under the Crawler, and we have a large surface area for the test equipment on top.

I used Synchronous Gear Pulleys for the power transfer from the Worm Gear Motor to the wheels. The Synchronous Gear Pulleys have teeth in them like a gear. The Gear Belts have matching teeth which make this drive train Synchronous, meaning all four corners move at the same rate. There is one belt that couples the Worm Gear Motor to the first drive shaft, and a second belt which couples the first drive shaft to the second drive shaft. The length of the belt is determined by the distance between the shafts, and the outside diameter of the gear pulleys. Two times the distance between shafts plus the outer circumference of one of the gear pulleys. In this case the distance between shafts is 5.9 inches, and the pulley outside diameter is 1 inch, so a 15" Gear Belt was the one.

Now that I have built a Synchronous Four Wheel Drive I'll need to apply this to some other things. For this Crawler Test Platform 0.1 MPH is the goal, but I can see the next one being a little more powerful. The next step in this process involves Speed Control. The one factor I have control of we can use to vary the speed of the Crawler is the Voltage applied to the Worm Gear Motor. This motor can go from 6 to 15 Volts, and move the platform. Previously I had blogged about using a PIC to do Speed Control using Pulse Width Modulation of a DC Motor. That same control system will get used here to do speed control on the Crawler. I'm also looking at using the PIC to get wireless communications to, and telemetry back from the Crawler. The device we are testing sends data back to a piece of test software running on a computer. So the crawling part of the Crawler is done, now I need to get to work on the brains... Brainz!

Sunday, February 21, 2016

Seized O2 Sensor

My best tool for working on cars now is the interwebs. So, I found out that code 1155 is the Oxygen Sensor on the Second Bank of the motor, which is the front bank, and code 1135 is the Oxygen Sensor on the rear bank. So, I changed the wrong sensor. The plan at this point was to replace the front Oxygen Sensor with the one I removed from the rear. This is where I had a kink in my plans. The front Oxygen Sensor was seized in the exhaust manifold.

The rear Oxygen Sensor was tough to break loose, but easy to turn after that, finger tight. The front Oxygen Sensor broke loose, then was totally stuck. There are a number of specialized tools for Oxygen Sensors that are all 7/8 inch. First its the wrong size, the nut on the Oxygen Sensor is 22mm. Plus open ended wrenches are not going to work in a seized bolt situation because they stretch when you put a lot of torque on them. So the specialized Oxygen Sensor Wrenches are out, and the open ended combination wrench was out. They only rounded off the corners of the nut.

In order to remove the Oxygen Sensor I literally had to break it off. I used my Blacksmith Hammer, and an Iron Bar to break off the stem of the Oxygen Sensor. Its a metal tube with a ceramic interior, so you'll crack the ceramic by hitting it, and de-swage the metal tube from the nut part of the sensor in the exhaust manifold. With the stem removed you can then use a regular 22mm, 6 point, 1/2 inch drive socket, and a heavy duty driver to force the remaining part of the Oxygen Sensor out of its hole. I also had the Blacksmith Hammer to move the socket driver. This sensor did not want to come out, and it took some threads with it. The Oxygen Sensor was literally welded to the treads of the Exhaust Manifold. After getting the old sensor removed then I had to deal with the damaged threads. There is a tool called a Thread Chaser which is a specialized Tap which will clean up the damaged threads. Its in the Tool picture above, on the right with the Anti-Seize Compound. You could also use thread cutting oil for tapping the threads. So I ran the Tap in, and out a few times, then the new sensor went in easy, and sealed, the threads are saved, Yay! The Check Engine light went off the second time I drove the Truk. That was a good project for a rainy weekend...